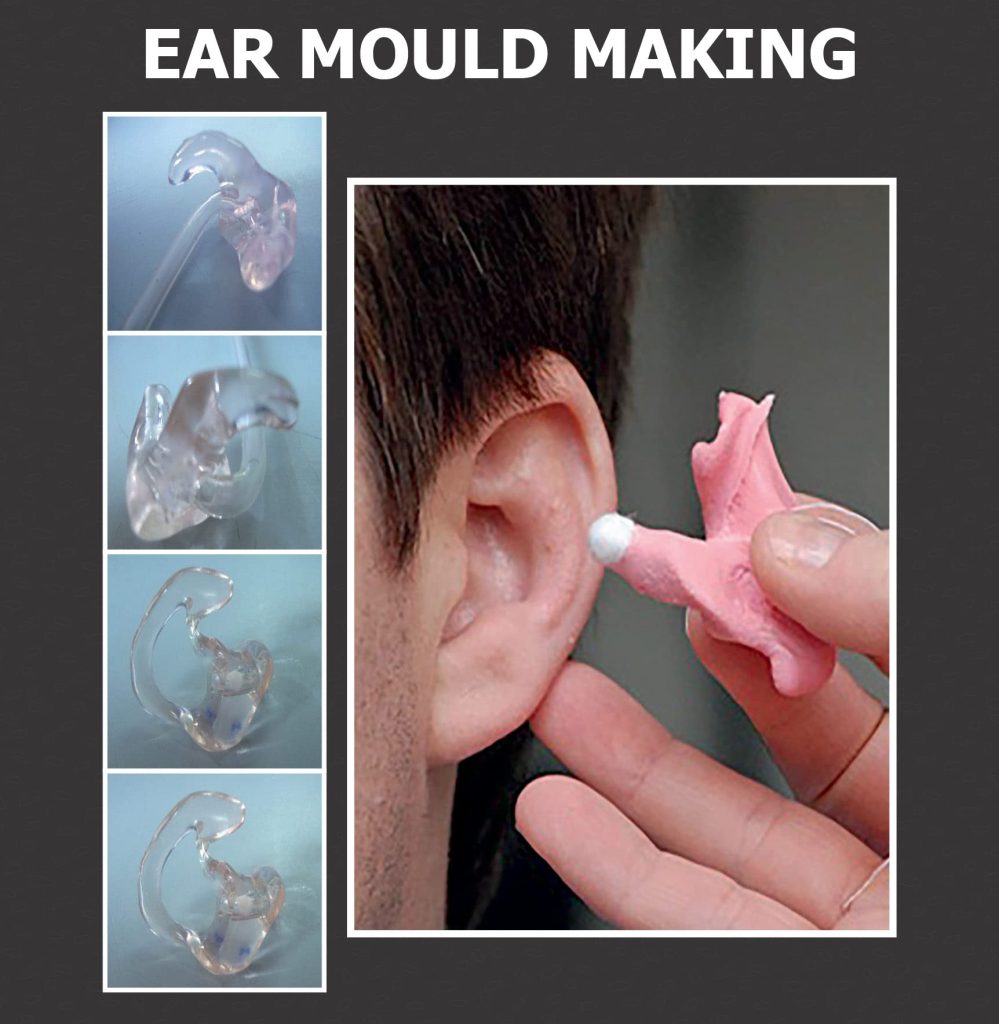

The process for making an ear mold involves taking an impression of the ear, then using that impression to create a virtual model and a physical mold: StepDescriptionImpressionA soft putty, usually silicone, is filled into the ear to create a replica of the ear’s shape.

A clinician will perform an otoscopy to ensure the ear canal is clear of any objects before inserting the putty.ScanningDigital cameras capture the impression to create a “point cloud” or “wire-frame”. A computer then creates a virtual model of the impression.ModelingA technician uses 3D modeling software to modify the virtual impression and create a virtual hearing aid shell.PrintingThe shell or ear mold is printed using either Selected Laser Sintering (SLS) or Stereo Lithographic Apparatuses (SLA).